A flange is a critical mechanical component used to connect pipes, valves, pumps, fittings, or other equipment to form a piping system. It provides accessible assembly, disassembly, inspection, and modification points.

1. Core Functions & Purpose

Connection: Joins pipe sections or equipment securely.

Sealing: Creates leak-tight joints using gaskets compressed between mating flanges.

Access: Facilitates maintenance, cleaning, or inspection without cutting pipes.

Structural Support: Transfers loads (pressure, vibration, weight) across the system.

2. Key Components of a Flanged Joint

Flange Pair: Two identical or compatible flanges bolted together.

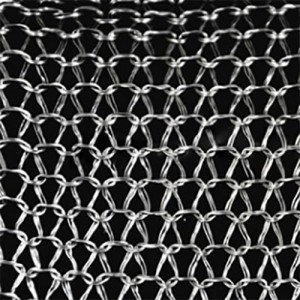

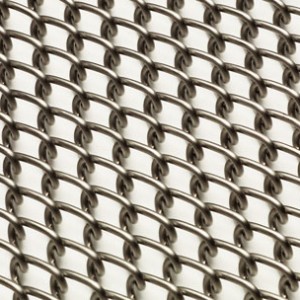

Gasket: Compressible material (rubber, graphite, PTFE, metal) placed between flanges to seal imperfections.

Bolting: Studs, nuts, and washers that apply clamping force to compress the gasket.

Flange Types (Common Classifications)

By Attachment Method

| 中文类型 | 英文名称 | 特点及应用场景 |

| 平焊法兰 | Slip-on Flange (SO) | 安装简便,适用于低压、中温管道系统,焊接量少,成本较低。Slides over pipe & fillet-welded (inside/outside).Easier alignment; lower cost; suited for low/medium pressure. |

| 对焊法兰 | Weld Neck Flange (WN) | 颈部壁厚与管道一致,强度高,适用于高压、高温或腐蚀性介质管道。Long tapered hub for stress distribution.Ideal for high-pressure/temperature systems. |

| 承插焊法兰 | Socket Weld Flange (SW) | 适用于小口径管道(DN≤80),焊接强度高,密封性好,减少介质滞留。Pipe inserted into socket & welded (fillet weld).Good for small-bore, high-pressure systems. |

| 螺纹法兰 | Threaded Flange (TH) | 无需焊接,通过螺纹连接,适用于低压、小口径管道或可拆式连接。Internal threads match pipe’s external threads.Used where welding isn’t safe (e.g., explosive environments). |

| 松套法兰 | Lap Joint Flange (LJ) | 法兰环可活动,适用于腐蚀性介质,便于更换,减少管道应力。Uses a stub end + backing flange.Allows easy rotation for alignment; ideal for frequent disassembly. |

| 盲板法兰(盲法兰) | Blind Flange (BL) | 用于封堵管道末端,无通孔,起到隔离或检修作用。Closes pipe ends/vessels; handles high pressure. |

| 整体法兰 | Integral Flange | 与设备或管道一体成型,强度高,适用于高压、高载荷工况。Integrally formed with equipment or pipelines, featuring high strength and is suitable for high-pressure and high-load working conditions. |

By Face Type

|

英文 |

中文 |

密封原理 |

|

Raised Face (RF) |

凸面法兰 |

凸起环压紧垫片(最常用)Raised ring (typically 1/16″–1/4″) concentrates pressure on gasket (most common). |

|

Flat Face (FF) |

全平面法兰 |

整个端面接触,用于低压/脆性材料Full contact with gasket; for low pressure/cast iron equipment. |

|

Ring-Type Joint (RTJ) |

环连接面法兰 |

金属环嵌入凹槽,高压高温密封Metal ring gasket in a groove; for high pressure/temperature (e.g., oil & gas). |

|

Tongue and Groove (T&G) |

榫槽面法兰 |

凸榫+凹槽互锁,精准密封Interlocking faces; common in pump/valve covers. |

|

Male-Female (M&F) |

凹凸面法兰 |

凸面嵌入凹面,防压溃Similar to T&G but with raised/recessed surfaces. |

4. Materials & Standards

Materials: Carbon steel (ASTM A105), stainless steel (A182 F304/F316), alloy steel (A182 F11/F22), duplex, brass, PVC.

标准体系(Standards)

|

英文标准 |

中文对应 |

适用范围 |

|

ASME B16.5 |

美标法兰 |

NPS ½”-24″ (压力等级150~2500) |

|

ASME B16.47 |

大直径美标法兰 |

NPS 26″-60″ (分A/B系列)(NPS 26″ to 60″). |

|

EN 1092-1 |

欧标法兰(PN系列) |

PN 2.5~PN 400 (公称压力) |

|

API 6A |

API井口法兰 |

石油天然气井口设备专用 Wellhead/Christmas tree flanges (oil/gas). |

|

JIS B2220 |

日标法兰 |

日本工业标准 |

5. Pressure Classes & Ratings

参数与标准Parameters & Standard

公称直径(DN):管道内径的名义尺寸,如 DN50、DN100。

Nominal Diameter (DN):Nominal size of pipeline inner diameter, e.g., DN50, DN100.

公称压力(PN):表示法兰的承压能力,单位为 MPa(如 PN16=1.6MPa)。

Nominal Pressure (PN):Indicates the pressure-bearing capacity of the flange, unit: MPa (e.g., PN16 = 1.6MPa).

密封面形式:平面(FF)、突面(RF)、凹凸面(MFM)、榫槽面(TG)等。

Face Type:Flat Face (FF), Raised Face (RF), Male and Female Face (MFM), Tongue and Groove Face (TG), etc.

材料:碳钢(CS)、不锈钢(SS)、合金钢、铜合金等。

Material:Carbon Steel (CS), Stainless Steel (SS), Alloy Steel, Copper Alloy, etc.

ASME Classes: 150, 300, 600, 900, 1500, 2500 (higher = higher pressure capacity).

PN Ratings: PN 10, PN 16, PN 40, etc. (nominal pressure in bar).

Note: Pressure rating decreases as temperature increases (refer to ASME B16.5 tables)

6. Gasket Selection垫片选型 /垫片选用

| Gasket Type | Material | Application |

| Non-Metallic | Rubber, PTFE, Graphite | Low-pressure/temperature; non-critical. |

| Semi-Metallic | Spiral Wound (SS+Graphite) | Most industrial systems (RF flanges). |

| Metallic | Ring Joint (Oval/Octagonal) | High-pressure/temperature (RTJ flanges). |

7. Critical Design Considerations

Bolt Load: Adequate torque ensures gasket compression without damaging flanges.

Flange Facing: RF vs. FF compatibility prevents uneven stress.

Corrosion: Material must match fluid/service conditions (e.g., SS 316 for chlorides).

Thermal Expansion: Mismatched materials can cause leaks during temp. cycles.

Alignment: Parallelism and coaxiality are essential for seal integrity.

8. Applications

Oil & gas pipelines

Chemical/petrochemical plants

Power generation (steam, water)

Shipbuilding, HVAC, water treatment

Pharmaceutical/food processing (sanitary flanges)

9. Installation Best Practices

Clean flange faces and gasket surfaces.

Align flanges without forcing bolts.

Use crisscross bolt tightening sequence.

Torque bolts gradually to specified values.

Verify joint integrity with pressure testing.