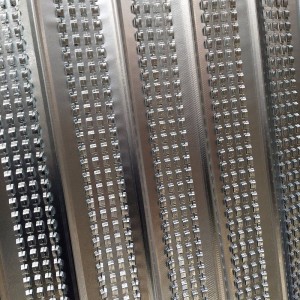

Interior Wall Galvanized Expanded Rib Lath 600MM Width 2500MM Length

Detailed Product Description

| Place of Origin: | CHINA | ||

| Brand Name: | CR | ||

| Certification: | ISO9001-2008 | ||

| Model Number: | RIB LATH | ||

| Minimum Order Quantity: | to be order | ||

| Packaging Details: | 6 pallet ,20pcs/bundle,50bundle/pallet | ||

| 6 pallet,20pcs/bundle,30bundle/pallet | |||

| Total : 9600pcs-19000pcs /20’GP container | |||

| Delivery Time: | 7 work days | ||

| Payment Terms: | L/C, T/T, Western Union | ||

| Supply Ability: | 10000 square meter per 16 days | ||

| Material: | Galvanized Steel | Thickness: | 0.2mm-0.6mm |

| Rib Distance: | 75mm, 100mm, 150mm | Size: | 600mmx2400mm |

| Small Order: | Support | Sample: | Support |

Specification of Interior Wall Galvanized Expanded Rib Lath

| Thickness(mm) | Rib Distance(mm) | Weight(KG) | Width X length(mm) |

| 0.20 | 100 | 1.25 | 600 x 2500 |

| 0.30 | 100 | 1.79 | 600 x 2500 |

| 0.35 | 100 | 2.09 | 600 x 2500 |

| 0.40 | 100 | 2.38 | 600 x 2500 |

| 0.45 | 100 | 2.68 | 600 x 2500 |

| 0.5 | 100 | 2.98 | 600 x 2500 |

| 0.30 | 150 | 1.31 | 600 x 2500 |

| 0.40 | 150 | 1.75 | 600 x 2500 |

| 0.45 | 150 | 1.96 | 600 x 2500 |

| 0.5 | 150 | 2.17 | 600 x 2500 |

| Note: Besides those above mentioned specification,the others can be made according to customer's requirements. | |||

Drawing Interior Wall Galvanized Expanded Rib Lath

Advantages of Interior Wall Galvanized Expanded Rib Lath

There is a reinforced mesh (a type of free template network).

It is made of steel strips cut and stretched by professional machines.

Is a completely jointless expanded steel mesh,

Made of pre-galvanized strip or 304 stainless steel,

Due to its special mesh and its mesh surface, there is a uniform V-shaped rib structure.

Applications of interior wall galvanized expanded rib lath

| project show of rib lath | application of rib lath |

| 1. High and low-rise residential light compartments, firewalls; 2. Construct a partition, a compartment; 3, the floor of the building, the partition wall; 4. Permanent interior and exterior walls and walls of permanent buildings; 5, the basement moisture-proof duplex wall. 6. Work seams with structural combination; 7. Tunnels, sewers, and wall works; 8, cutting foundation, dock, retaining wall; 9, flat and arched floor; 10. Nuclear power plant, storage tank and other arc-shaped structures; 11. Special projects such as landscaping sculptures; 12. Slope protection, earth embankment and other projects. |