-

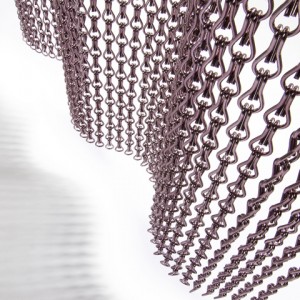

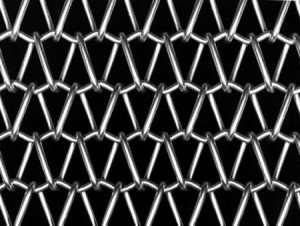

Chainmail Curtain for Interior or Exterior Decoration

Chainmail curtain, also named as ring mesh curtain, is an emerging type of architectural decorative curtain, which is similar to the craft of ring mesh curtain. Recent years, chain mail curtain has been constantly increasing prevalent in decoration. The new idea of connecting rings presents a refreshing appearance that has become a range of options for designers in the field of architecture and decoration. Made from stainless steel, an environmental material, chainmail curtain features multifunctional, practical, and good decorating effect with any sizes and colors. The ideal designed curtain, providing flexibility and transparency, has been widely applied as building’s facade, room dividers, screen, suspended ceilings, curtains, balcony and more.

-

Aluminum Chain Link Curtain/Chain Fly Screen

Chain link curtain, also named chain fly screen, is made from aluminum wire with anodized surface treatment. As we all know, aluminum material is lightweight, recyclable, durability and has flexible structure. This ensures chain link curtain has excellent rust resistance and good fire prevention properties.

-

Versa-Link™ Wire Mesh Conveyor Belt

Metal conveyor belt simplified!

Versa-Link™ stainless steel conveyor belt makes installing your conveyor belt quick and easy! Versa-Link’s Advanced Link Rods join the conveyor belt together in as little as 30 seconds with no tools required. Forged Edge Technology creates an edge that is flush with the side of belt, eliminating any catch points that can damage your belt during operation. With up to 81% open area, Versa-Link™ provides maximum air/liquid flow through capabilities that is great for frying, cooking, coating, and cooling applications. Versa-Link™ is USDA Accepted, with a clean-in-place design that saves time during sanitation. -

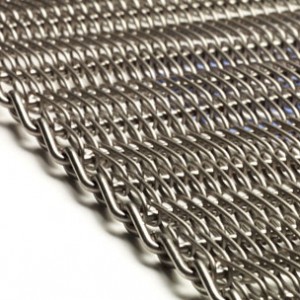

Stainless Steel Ladder Conveyor Belt

Ladder Belting is a simple but effective style of conveyor belt, commonly found in bakeries. Its open design provides efficient operation with minimum maintenance as well as facilitating easy and thorough cleaning.

-

Honeycomb Wire Mesh Conveyor Belt

Honeycomb belting, also known throughout the industry as Flat Wire belting, is a straight-running belt with an extremely high strength-to-weight ratio. It is available in a wide variety of aperture configurations to suit applications as diverse as casting, baking, drainage and packaging.

Honeycomb is constructed from formed flat wire strips connected by cross rods running through the width of the mesh. The rods are finished with either welded button edges or hooked edges.

-

Wire Mesh Conveyor Belt Flexible Rod type

Multi-tier spiral conveyor belts for the food industry

Flexible Rod belts are designed primarily for multi-tier spiral conveyors commonly used in the food industry. With the ability to side flex, the belt can also be used for conveyors arranged to go around obstacles. -

Wire Mesh Conveyor Belt Flat-Flex Type

Flat-Flex® XT® Advantages:

- Over 2X the life of standard belts

- More joints across the belt for longer belt life

- Up to 90% belt strength increase over standard Flat-Flex® belts

- Clean-in-place, wash down design

- Up to 78% open area for maximum air/liquid flow through

- Smooth carrying surface lessens product damage

- Available with C-Cure-Edge® loops

- Easily joined using Flat-Flex® XT® joining clips or EZSplice® joining strands

- USDA Accepted

-

Wire Mesh Conveyor Belt Flat-Flex Type

The unique features of Flat-Flex® conveyor belts offer numerous benefits that increase productivity, help contain costs and improve your overall product quality, including:

- Large open area – up to 86%

- Small transfers

- Non-slip positive drive

- Very low belt mass for improved operating efficiency

- Accurate tracking

- Hygienic design, Easy to clean, clean-in-place capability

- USDA approved

- C-CureEdge™ available on a range of selected specifications

-

Wire Mesh Conveyor Belt Flat-Flex Type Flat Spiral Type

The Flat Spiral belting is often found in baking and washing applications where small apertures are required alongside a flat conveying surface. Flat Spiral is also a preferred choice for end-users who have previously experienced tracking problems with other spiral woven meshes, as the alternating coil pattern helps reduce any tendency for the belt to veer to one side.

-

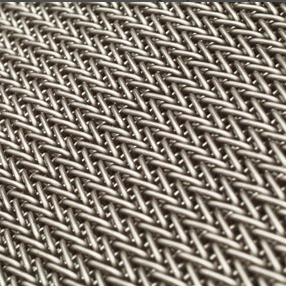

Stainless Steel Cordweave Conveyor Belt

Cordweave belts offer an extremely close and flat mesh for applications where very small items are being conveyed. Cordweave also provides a uniform heat transfer across the belt due to its high density and smooth carrying surface. These characteristics make Cordweave a popular choice in a wide variety of applications, ranging from biscuit baking to sorting small mechanical components.

-

Chain Link Conveyor Wire Mesh Belt

Chain Link belting is the simplest available wire belt design, suitable for light duty use in drying and cooling applications. Chain Link is a component part of Wire Belt Company’s Troughing Filter Belts, and can also be used as collapsible screen for applications such as lift guards.

-

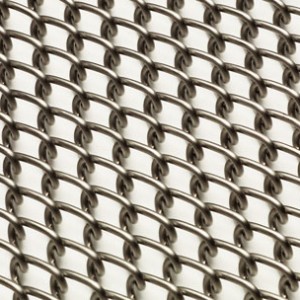

Balanced Spiral Woven Wire Mesh Belt

Balanced Spiral belt is an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications. Benefits of Balanced Spiral belt include straight-running operation, an excellent strength to weight ratio and an extremely wide variety of mesh specifications to suit each individual