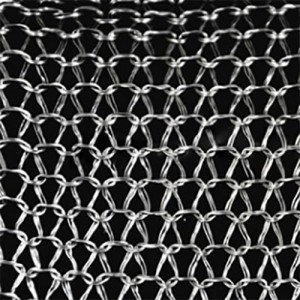

Working principle of demister pad

When the gas with mist rises at a constant speed and passes through the wire mesh, the rising mist will collided with the mesh filament and attached to the surface filament due to the inertia effect. The mist will be diffuse on the filament surface and the droplet will follow along the filaments of the two wire intersection. The droplet will grow bigger and isolate from the filament until the droplets gravity exceeding gas rising force and liquid surface tension force while there is little gas passing through the demister pad.

Separate the gas in the droplets can improve the operating condition, optimize process indicators, reduce corrosion of the equipment, extend equipment life, increase the amount of processing and recovery of valuable materials, protect the environment, and decrease air pollution.

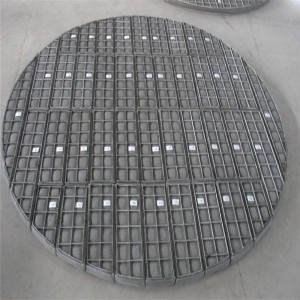

Mesh pad installation

There are two kinds of wire mesh demister pad, which are disk shaped demister pad and bar type demister pad.

According to different using condition, it can be divided into upload type and download type. When the opening is located in the above of the demister pad or when there is no opening but has flange, you should choose the upload demister pad.

When the opening is in the below of the demister pad, you should choose the download type demister pad.

Upload type demister pad

Download type demister pad

Horizontal separation tower

Spherical separation tower

Scrubber

Distillation column.

Vertical separation column

Packed tower

| Style | Density kg/m3 |

Free Volume % |

Surface Area m2/m3 |

Metex | York | Becoil | Knitmesh | Vico-Tex | Uop | Koch | Acs |

| H | 80 | 99 | 158 | Hi-Thruput | 931 | 954 | 4536 | 160 | B | 511 | 7CA |

| L | 120 | 98.5 | 210 | 422 | |||||||

| N | 144 | 98.2 | 280 | Nu-Standard | 431 | 9030 | 280 | A | 911 | 4CA | |

| SN | 128 | 98.4 | 460 | 326 | 415 | 706 | |||||

| SL | 193 | 97.5 | 375 | Xtra-Dense | 421 | 890 | 9033 | 380 | C | 1211 | 4BA |

| SM | 300 | 96.2 | 575 | ||||||||

| SH | 390 | 95 | 750 | ||||||||

| T | 220 | 97.2 | 905 | ||||||||

| R | 432 | 94.5 | 1780 | Multi-Strand | 333 | 800 | |||||

| W | 220 | 97.2 | 428 | Wound | |||||||

| GS | 160 | 96.7 | 5000 | 371 |

Related Pictures